The servo motor is an electric motor that allows continuous determination of exact positions, speeds, and torque using control electronics (servo controller). The software interface allows for precise parameterization and programming of the motor's actuation, giving it dynamism as well as individuality.

Although servo motors can be small and powerful, they are essential for

precise positioning control applications. A signal (data), also known as

a pulse width modulator (PWM), controls the servo motor. These are some

of the most common servomotor applications.

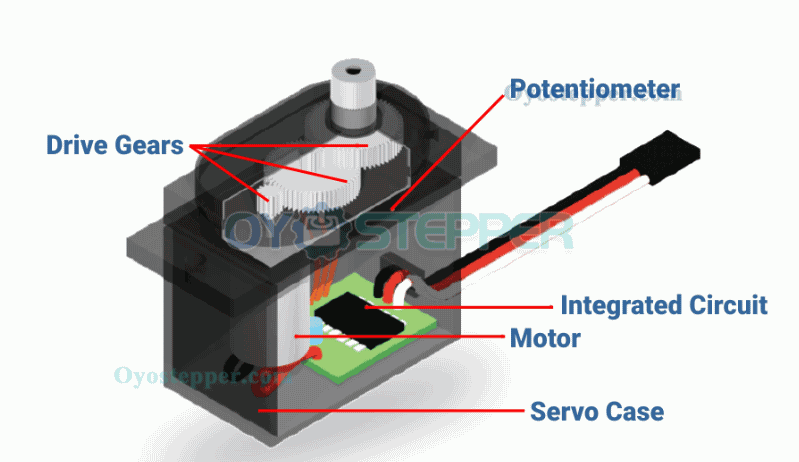

Construction of Servo Motor

This motor is a closed-loop mechanism that incorporates positional

feedback in order to control the rotational or linear speed and

position.

This motor is actually an assembly of four things:

Normal DC motor- That is in charge of generating the motion through its shaft.

Gear reduction unit/gear box

Potentiometer

Control circuit;

Advantages of Servo Motor

If a heavy load places on the motor, the driver will increase the

current to the motor coil as it attempts to rotate the motor. Basically,

there is no out-of-step condition.

High-speed operation is possible.

Disadvantages of Servo Motor

Since the motor tries to rotate according to the command pulses, but

lags behind. it is not suitable for precision control of rotation.

Higher cost.

When stopped, the motor’s rotor continues to move back and forth one

pulse. So that, it is not suitable if you need to prevent vibration.

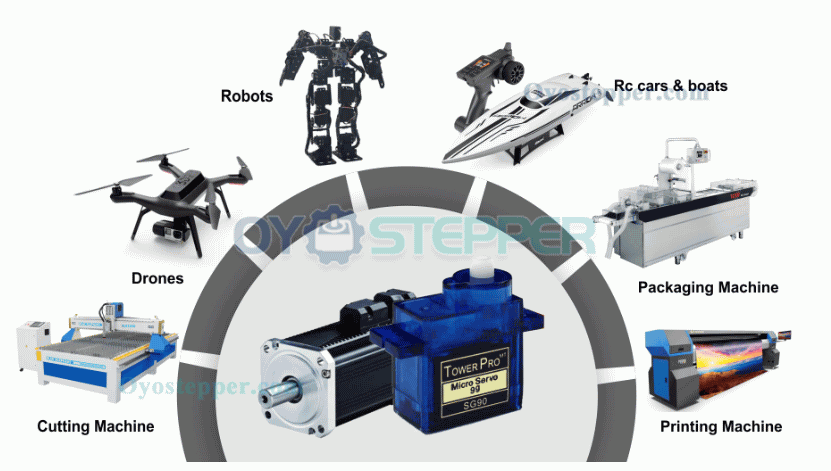

Function in many areas of use

The areas of use cover almost all areas of the manufacturing industry. In particular:

plastics industry

packaging machines

textile processing

printing technology

e-mobility

shipbuilding

energy technology

metalworking

pharmaceutical industry;

What are Servo Motors Used For?

China servo motors

can be used in many different applications. The advantages listed above

means that servo motors are used more and more in industrial

applications to replace conventional AC motors and stepper motors as

well as hydraulic and pneumatic systems. There are many applications

where servo motors have an advantage. Below are just a few examples:

Compared to the stepepr motor ,

servo motor offers great flexibility, precision, and reliability with

high cost efficiency. It can precisely actuate, hold and speed up

positions, torque and speeds in fractions of seconds. This allows

complex machine actions that can be used to implement complicated

production processes. They are also suitable for robotics or automation

solutions. Without servo motors, the world would be very different. They

make our lives easier and provide us with better products, no matter if

they are used in industrial manufacturing, or commercial applications.

See more:

https://www.oyostepper.com/article-1116-The-Advantages-and-Disadvantages-of-Servo-Motor.html

评论

发表评论