Generally speaking, high temperature resistant motors are defined by their insulation class. The field of stepper motors usually involves six insulation classes.

High temp stepper motors have special requirements for materials due to their use in high temperature situations, including enameled wire, skeleton, magnets, bearings, grease, end caps, etc., especially varnished wire, skeleton and magnets.

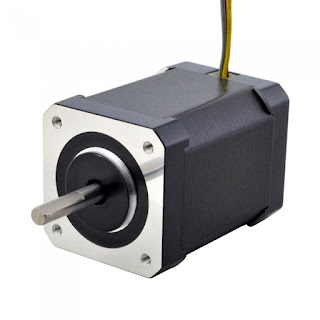

High temperature motorsfrom oyostepper.com are rated to operate in ambient temperatures between 50 degrees C and -20 degrees C. While this satisfies the majority of uses, there are certain applications that require the motor to operate at higher or lower temperature ranges than what standard motors allow for. Unfortunately, operating standard motors anywhere outside these temperature ranges will result in poor performance.

High Temperature Stepper Motor Frame size selection:

High Temperature Stepper Motors are typically made in groups or families, the families are identified by the outer diameter or size of the square, these references are called frame sizes. In the American system, a 23 frame is a nominal 2.3 inches in diameter. For High Temperature Stepper Motors less than one inch in diameter, the reference is typically known as a size. Herein is a list of the frame sizes offered by Empire Magnetics Inc. and some of the characteristics of the group that will allow you to select from them.

Magnet performance degrades at high temperatures unless a special alloy with high-temperature tolerance and high curie point is used—similar to what might be used in a space or vacuum motor depending on the application. For these applications, the wire has to have special insulation that can tolerate high heat as well. Upgraded insulation also helps to reduce stress fractures doe to heat-up and cool-down cycles. Type II motors require additional insulation material to prevent burnout.

Currently, the high temperature motors in our catalog are of class H, which allows a maximum temperature of 180 degrees Celsius and an allowable temperature rise of 125 degrees Celsius.

Of course, we can also customize stepper motor of other levels of high temperature motors, so you can contact our technical team.

Growth factors of the Permanent Magnet Stepper Motor Market

评论

发表评论